The Li-ion battery industry is essential for the future of Europe from all points of view: economical, technological, environmental, and more.

IN-CORE Systèmes as a key player on the manufacturing process of li-ion batteries participated at the Battery Show in Stuttgart that was held last May.

With more than 450 exhibitors showcasing their solutions and latest developments in battery and H/EV technology.

Trends in Li-ion Batteries industry

Two main targets of the European Union for a clean planet are:

– Decarbonization of mobility, this means electric vehicles and different levels of hybridization

– Decarbonization of Europe’s energy supply, this means renewable energy and therefore better battery energy storage

The transition to an all-electric future will require a global strategy including legislation, R&D, large-scale manufacturing investment and better charging infrastructure among others.

The creation of an EU-based li-ion battery cell production is a long term strategic goal; not only to compete with Asia and become second largest manufacturer in the world, but also to guarantee a more sustainable batteries manufacturing.

The future is bright for Electric cars:

Today, The EV battery is around 33% of the car’s total cost. By 2025, analysts predict that the battery will be only 20% of the total vehicle cost. Moreover, the cost cross over point between electric car and combustion-engine car will be, according to experts, in 2022 for large vehicles in the European Union.

Cells are the most significant part of the battery’s cost, meaning that battery innovation occurs at the cell level and large-volume, efficient manufacturing.

What can be improved for Li-ion batteries production?

Manufacturing effectiveness will be a key factor towards large-scale manufacturing in Europe. Cost continues to be an issue and will need to be addressed by the development of a robust supply chain, standards in manufacturing, high manufacturing throughput and streamlined low-cost processing methods.

Automatic optical inspection solutions (AOI) will play a main role allowing to improve quality, reduce waste and improve yield.

In-line optical inspection solutions can focus on reduce process variability. Focusing on the factors responsible of process variation will eventually contribute to the control over the cell performance.

IN-CORE Systèmes role in the Li-ion batteries industry

IN-CORE is involved in Li-ion batteries’ electrodes manufacturing inspection for more than a decade.

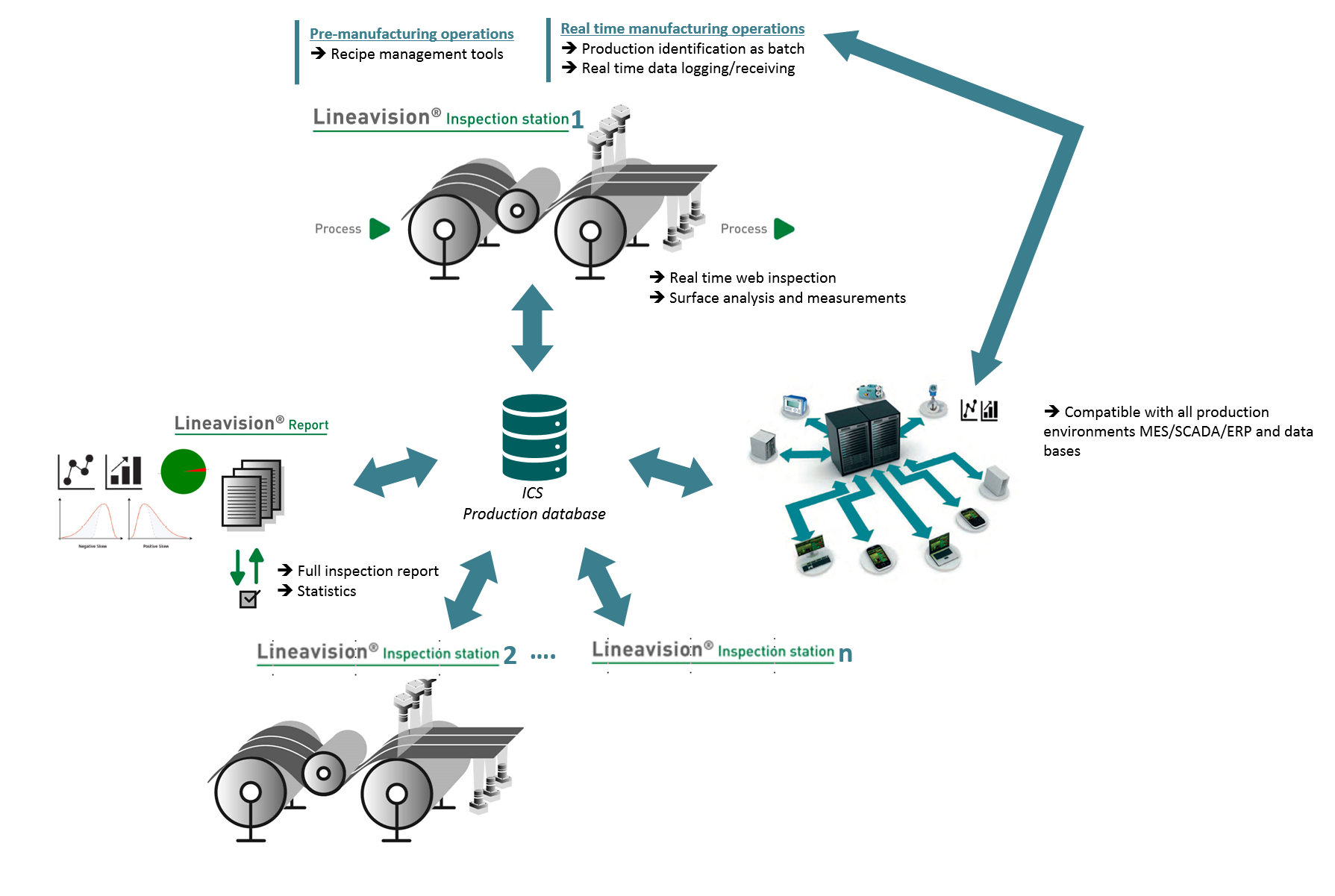

The optical inspection systems with IN-CORE’s lineavision software are integrated and installed on coating lines for surface defect detection and geometrical control of both up/lower coated surface.

Main quality Control proven inspection solutions for electrode manufacturing are :

Defect detection:

- raw material (foil defect, surface cleanliness)

- coating defects/homogeneity

- drying (micro cracks,…)

- coated patterns regularity (dimension, overlapping, edges, …)

- calendering (pressure, homogeneity, temperature,..)

Measurements: geometrical properties control with tolerances of ±0,5 mm

- coated lanes/patterns position,

- width,

- overlapping (upper/lower coating misalignment detection),

Traceability highly adaptable with the system fully compatible with all production environments:

- recipe management

- product identification (batch, job, roll number)

- real time data logging/receiving

- full inspection report with time series data logging

More information about High Resolution Inspection Systems ?

Please feel free to contact us !