25/06/2020

IN-CORE Systèmes as strategic partner for the Printed Electronics industry is participating at the 10th Printed Electronics edition next September 9th 2020.

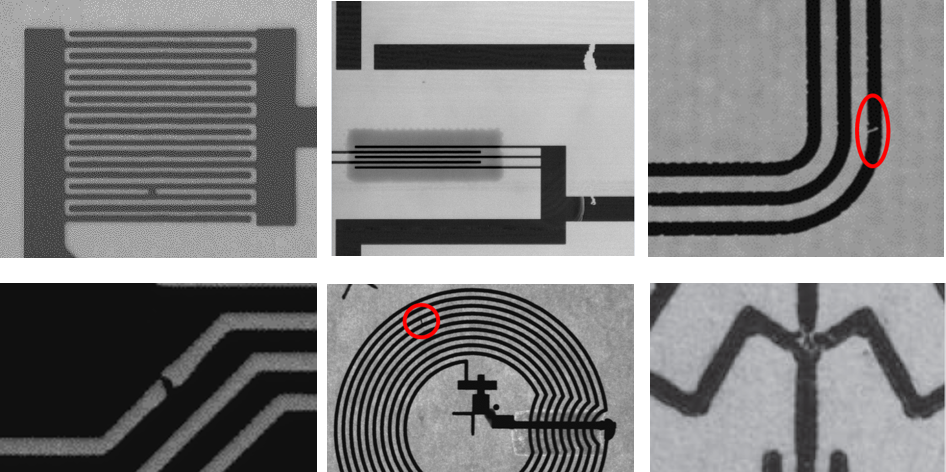

IN-CORE Systèmes delivers industrial inspection and traceability solutions for printed electronics which enable to control the quality of coating or printing steps for layers, circuits, modules, rolls, etc.

Standalone inspection station easy to install on existing production lines at appropriate inspection locations.

Lineavision inspection performances for printed electronics application

- Web inspection: the system detects defects

- Measurement and dimensional controls:

- The system controls the alignment/misalignment of the different layers.

- The system measures the bandwidth and the inter-band width

- Circuits:

- Registration of circuit components printed in multiple steps

- Multi regions of interest per circuit

- Adapted control to each region of interest

- Data in-line processing:

- The system automatically classifies all defects in order to alert (audible alarm and/or light alarm) in case of problems and drift with respect to target values

- The system indicates the precise location of defects, size and other measurable characteristics

- Data off-line processing:

- The system allows the storage of inspection reports with all information

- The system allows the exploitation and export data

Using the latest technology of linear video sensors with LED line light, the LineaVision+ system catches all surface defects, and checks surface characteristics regularity. The system detects all anomalies and immediately notifies the operator for potential instant action.

The operator interface is configurable to provide manufacturing-oriented screens that contain relevant information for line process control.

Inspection reports are stored for post-process use: statistics, defining the quality grade of each roll or sheet, preparing and planning the downstream operations, production traceability, etc.