PRINTED ELECTRONICS

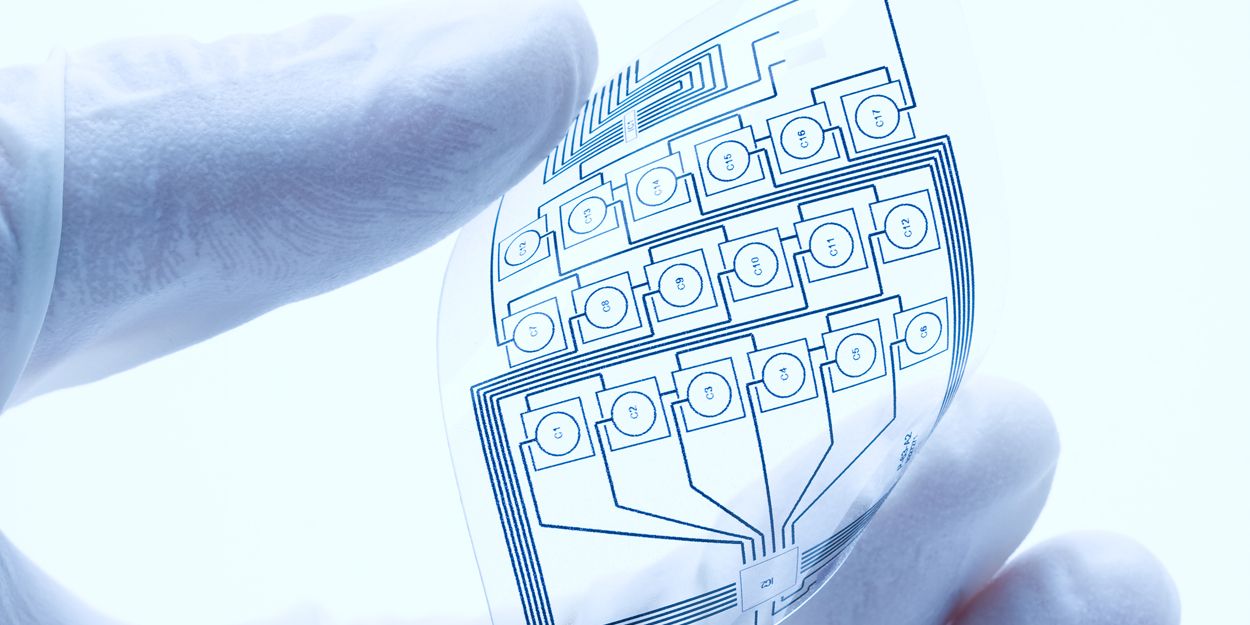

Flexible printed Electronics high-resolution and traceability solutions

IN-CORE Systèmes delivers industrial inspection and traceability solutions for printed electronics which enable to control the quality of coating or printing steps for layers, circuits, modules, rolls, etc.

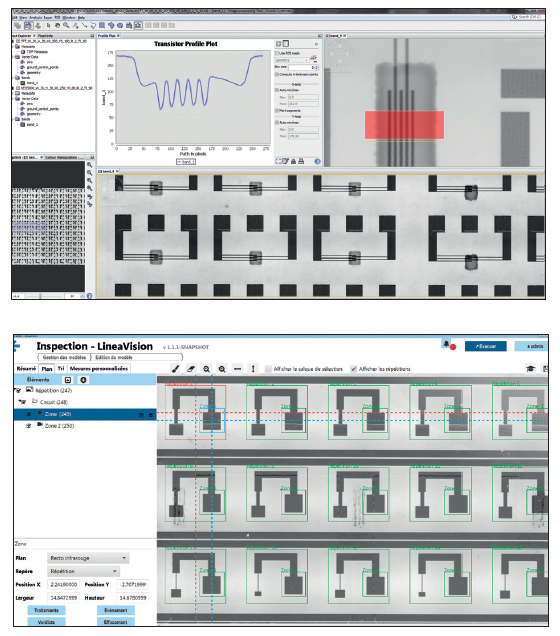

Each step of the process is controlled to highlight crucial defects such as:

- Short circuits,

- Circuit breaks,

- Lack and excess of inks

- Inclusions of foreign particles

The system also monitors:

- Absolute position of patterns or layers

- Quality and registration of circuit components

For further information on printed electronics solutions, please download our brochure.

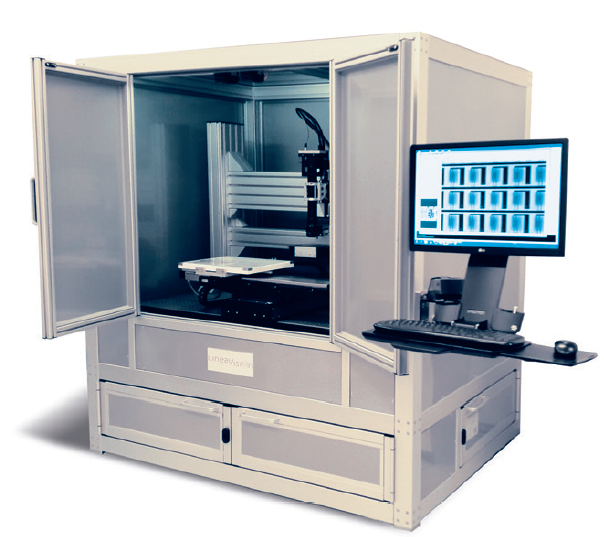

High-resolution inspection and characterisation platform

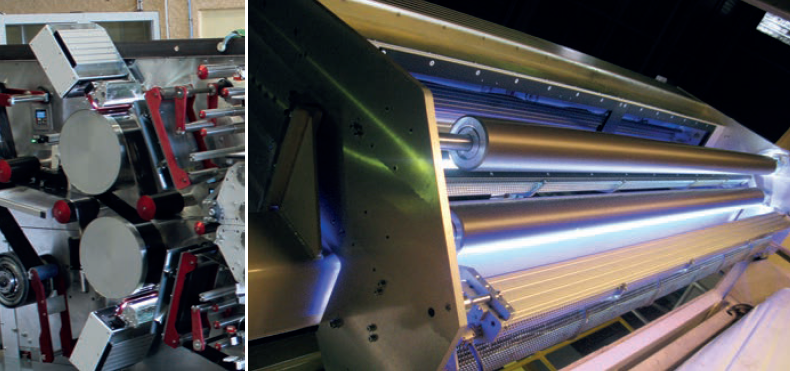

LineaVision platform, based on high-resolution image analysis on printed electronics surfaces enables non-contact inspection and measurements.

Using advanced characterisation capability, the platform analyzes single and multilayer structures for defining and assisng quality and various manufacturing process steps.

Modular high-resolution solution

- Inspection of either rigid, semi-rigid and flexible substrates

- Integration on production processes

- Clean room environment suitable

Product yield optimization

- Control process deviations

- Correlate visual detection results with electrical failures

- Major waste reduction and quality compliance

IN-CORE is an active memeber of AFELIM, the French Association of Printed Electronics, whose mission is to create a network to discuss the challenges of the Printed Electronics industry towards mass production.

For more information on more of our partnerships, please click here.