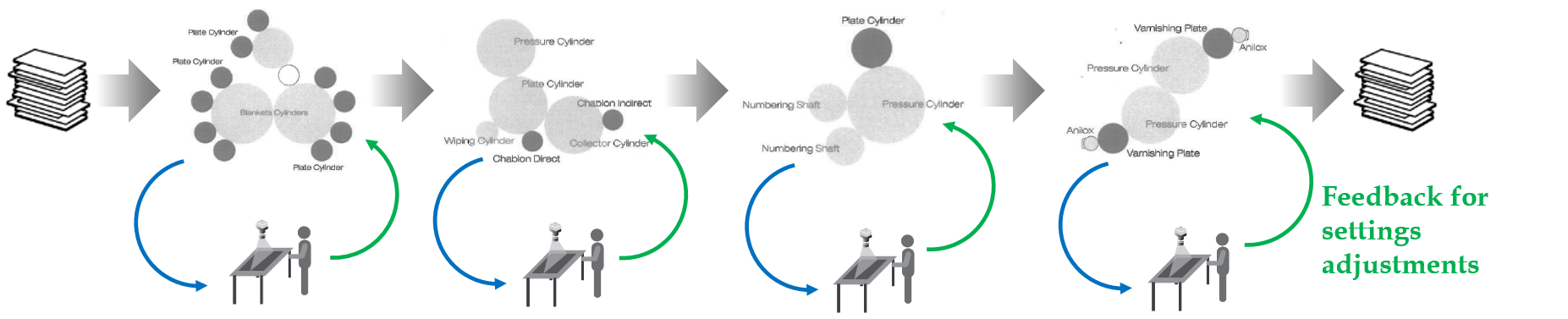

Build quality into the process to identify and correct causes of quality problems

The banknote industry faces different challenges:

- How to modernize and transform the existing quality control infrastructure in the banknote manufacturing industry?

- How to standardize all process to avoid source of variabilities?

- How to integrate the adequate connected sensors into the manufacturing process?

IN-CORE strategic partner for the banknote manufacturing industry

IN-CORE has been addressing all these questions and challenges over the past 20 years. As a strategic partner of the banknote manufacturers (both at substrate making and high security printing levels), IN-CORE is always listening to the current and future needs of our customers.

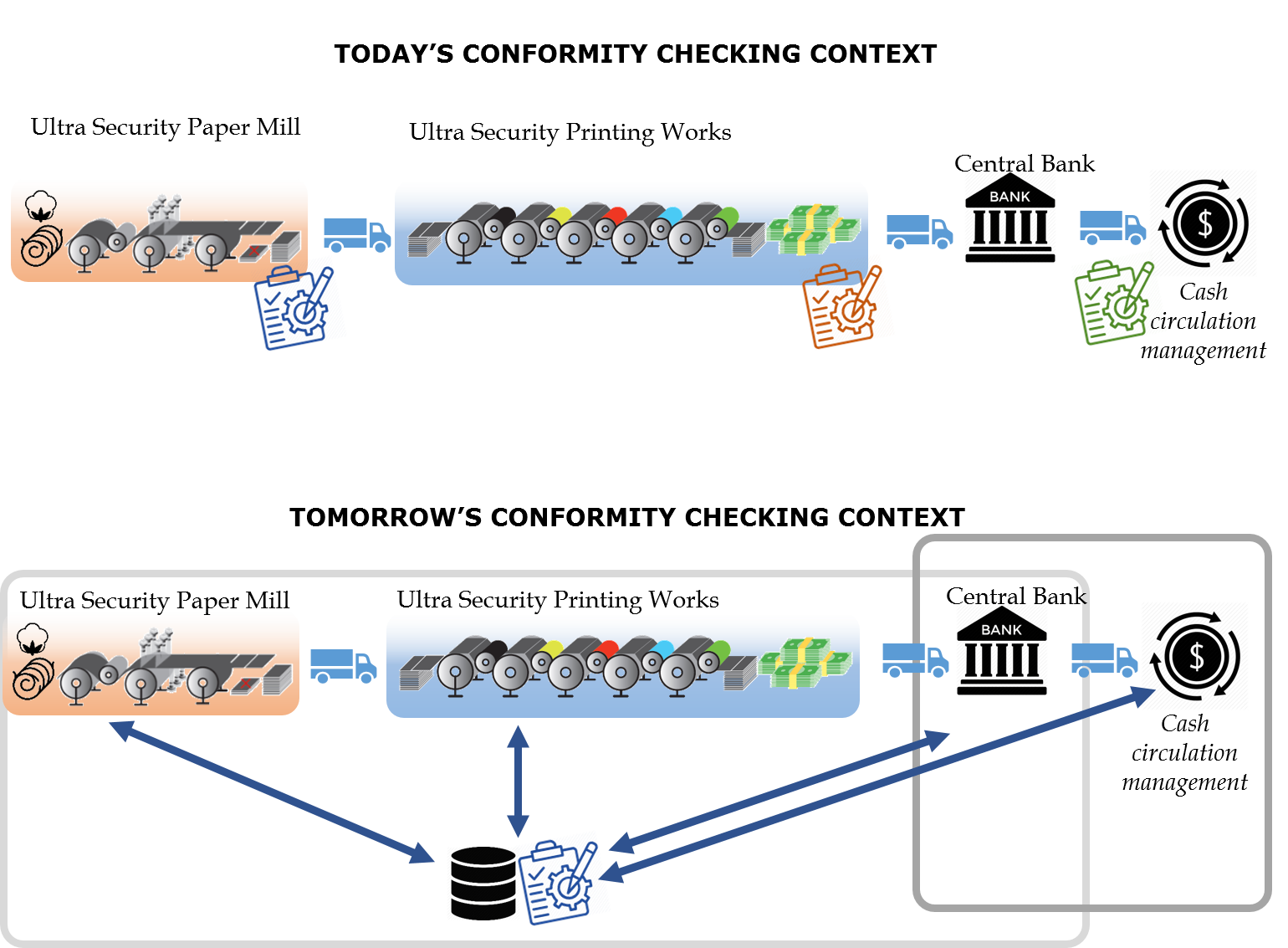

The cash industry faces a global challenge: how to make cash more efficient?

In order to:

- Fulfil high quality and security standards against counterfeiting,

- Increase banknotes’ durability during circulation

- Optimize all costs both at manufacturing level and cash circulation management

IN-CORE’s vision for global quality management foundations:

- In-Line Quality control

- Connected sensors

- Process standardization

- Total quality Management

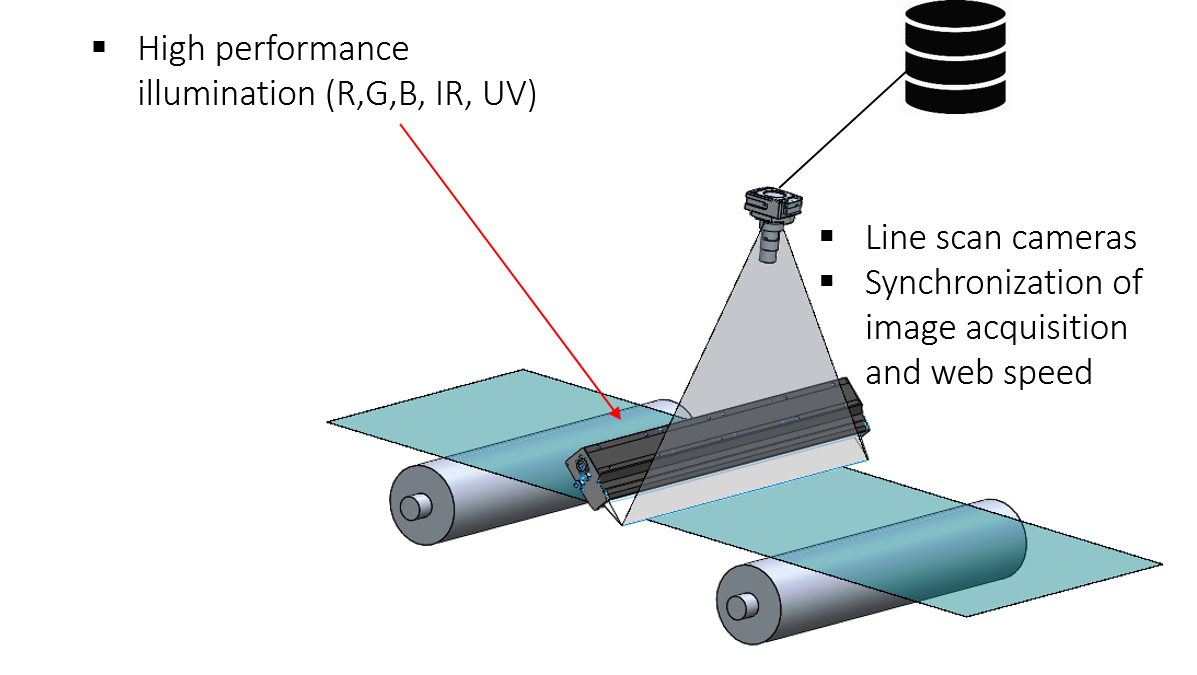

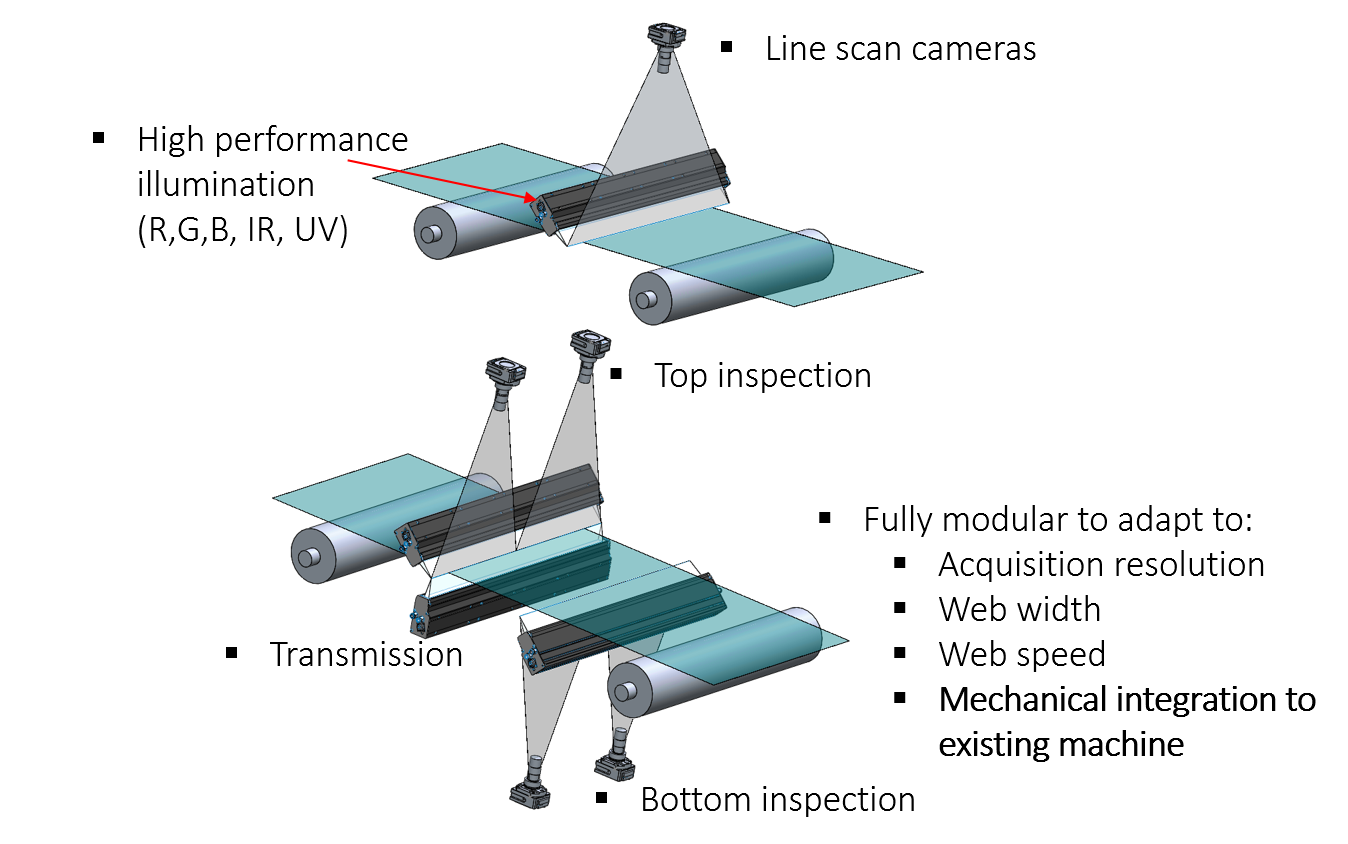

The sensors are based on high performance illumination (R, G, B, IR, UV) and line scan cameras (or CIS).

The sensors are fully modular to adapt to: the appropriate acquisition resolution, web speed, web width and mechanical integration to existing machine.

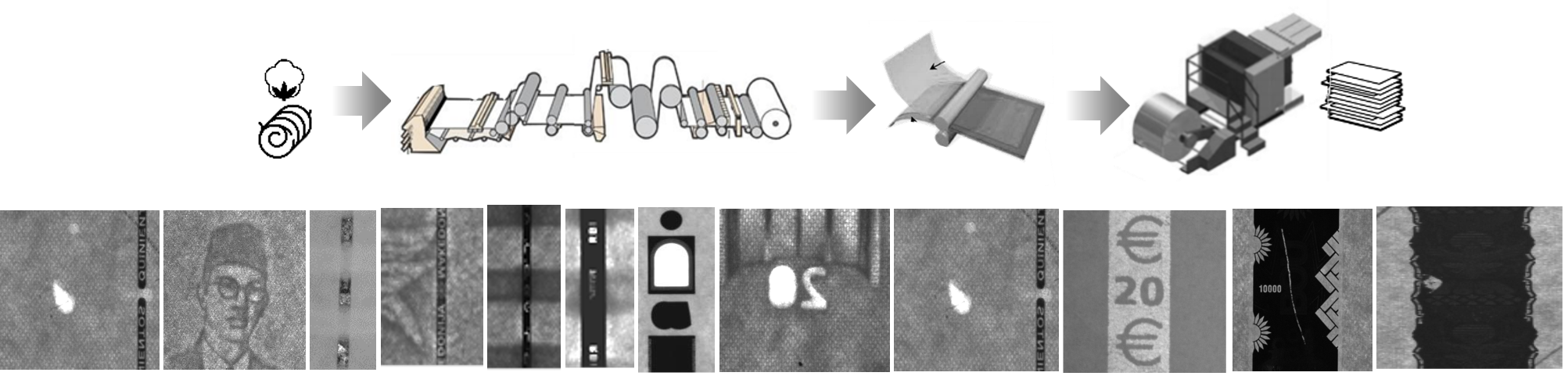

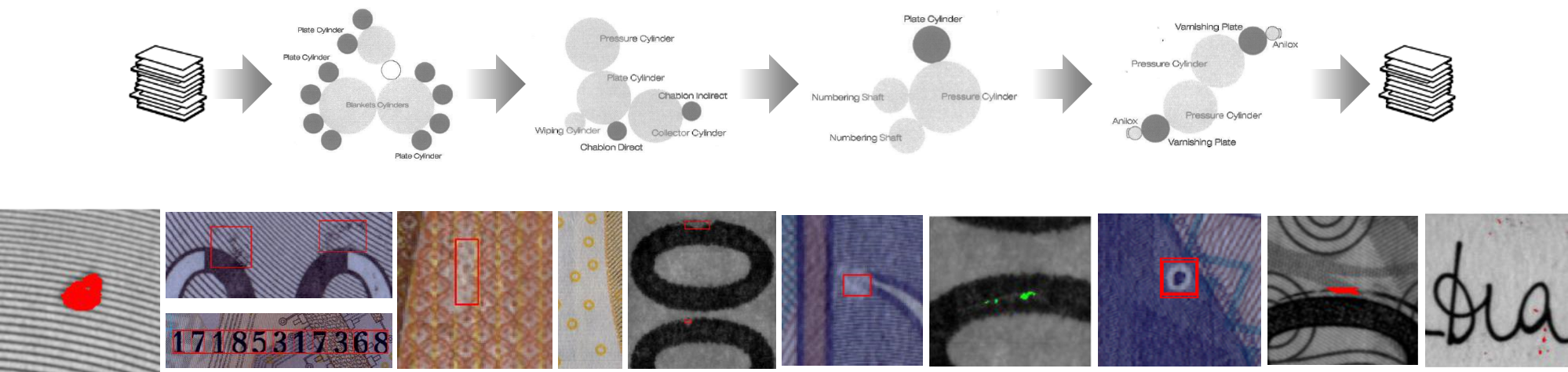

IN-CORE Systèmes has proven solutions at:

- Vision inspection solutions at paper Mill both wet and dry end

- Vision inspection solutions at iridescent printing and foil hot stamping machine

- vision inspection solutions for quality control, cutting and sorting on cross-cutter machine

- Vision inspection solutions on sheet to sheet automatic transport, inspection and sorting machine

- Vision inspection solutions on existing intaglio machines

- Vision inspection solutions on serigraphic printing machine

- Smart table off-line printing qualification equipment for reference definition for input to printing machin

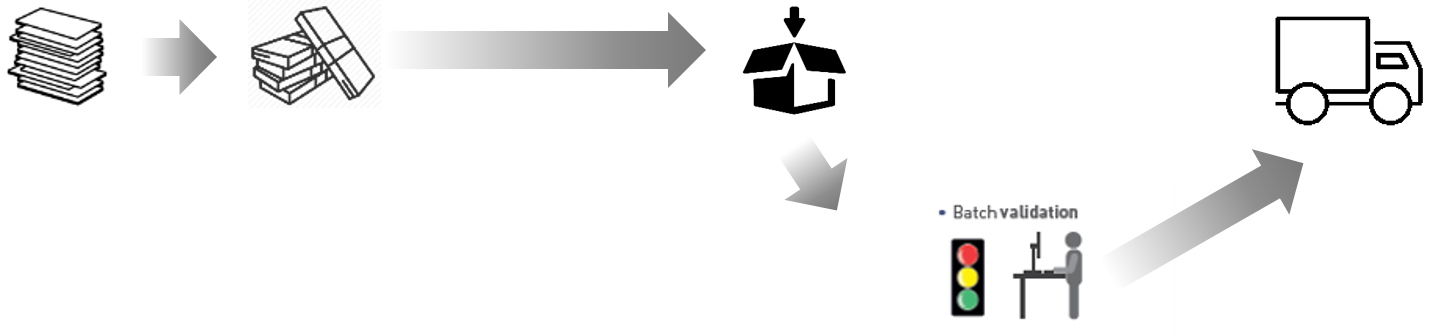

- Automatic single banknote inspection system for final checking of the produced batch or for inspection of ejected banknotes on the BPS for conformity checking validation and possible action to settings adjustment for banknotes ejection on the BPS

More information about High Resolution Inspection Systems ?

Please feel free to contact us !